Thermoset

As a major player in materials processing, CLAYENS has expertise in all stages of thermoset materials processing.

From polyester to moulding powder, we offer a wide choice of materials to help you design parts and equipment that can withstand the most extreme conditions.

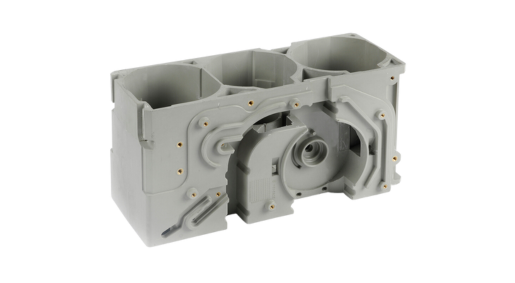

Design and manufacture of thermoset parts

Thermosets are the materials of choice for the manufacture of equipment and parts subjected to harsh environments. Their mechanical properties enable them to withstand a wide range of stresses such as UV, vandalism, adverse weather conditions and heat.

At CLAYENS, we know how to recommend the right manufacturing process, combining cost-effectiveness with the required mechanical performance.:

- Thermoset injection moulding

- Thermoset compression moulding

- Thermoset injection-compression moulding

- Thermoset machining

Excellent mechanical properties for demanding uses

The fiber length of thermosets offers greater design freedom and high strength.

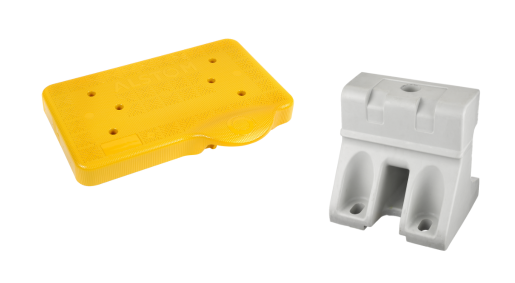

Materials for urban equipment

Urban equipment is sometimes exposed to malicious acts. CLAYENS can find the right chemical formula to manufacture highly resistant parts and equipment.

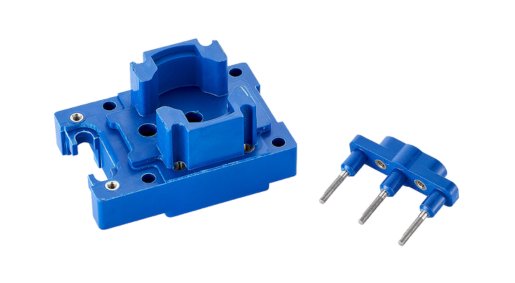

Materials for electrical insulation

We offer solutions for equipment requiring high levels of electrical insulation (fire and smoke resistance), such as electrical cabinets.

A wide range of processes to meet every need

Compression moulding avoids fiber breakage, while injection-compression can be used to achieve different objectives than injection moulding.

Thermoset technology is ideal for a wide range of uses

Electronic

Equipment

Aeronautic

Automobile

CLAYENS develops and invests in thermoset technology

Because both standards and your requirements evolve, CLAYENS does its utmost to continually offer you reliable and innovative thermosetting solutions.

A proactive R&D department

Continually striving for innovation, our R&D department works relentlessly to exploit the full potential of specific materials such as thermosetting polyesters and moulding powders for enhanced performance.

A to Z project management

From conception (size, design and materials) to manufacture, we can give you the answers and solutions you need to make your projects a reality. We can also provide "build to print" support.

An extensive fleet of machines

In order to meet all requirements, CLAYENS has a full range of machinery available, from the smallest to the largest presses (up to 1,000 tons).

An outstanding level of finishing

We apply the right finishing operations to remove any unwanted infiltrations, all for a result that fully meets your expectations.

Thermoset technology is ideal for a wide range of uses

CLAYENS, a key player in the manufacture of thermosets

The processing of thermosets is a complex and irreversible operation that requires very specific skills and resources for a successful outcome. That's why CLAYENS brings you its expertise, working with you step by step, from defining your project to delivering your parts from our various production sites. Using injection, compression or injection-compression moulding, we have already helped many companies create custom thermoset parts.

Talk to us about your next project!

Our Thermoset locations