Thixomolding

Innovative Technology for Magnesium Parts

Thixomolding is a semi-solid magnesium injection molding process that combines the benefits of die-casting and thermoplastic molding. It delivers superior strength, precision, and material efficiency.

What sets us apart is our Design for Manufacturing (DfM) approach. We work closely with you to refine your design, optimizing it for Thixomolding to ensure better performance and cost-effectiveness from the start.

With Thixomolding, you get a lightweight, high-quality solution tailored to meet your needs.

Benefits of Thixomolding

- Lightness and strength: Magnesium has a high strength-to-weight ratio, enabling the production of lighter, stronger parts.

- Precision and Finesse: Thixomolding enables the creation of very thin walls and tight tolerances, with exceptional dimensional stability.

- Durability and Corrosion Resistance: Thixomolding magnesium parts offer excellent corrosion resistance and enhanced durability.

- Thermal and electrical conductivity: Magnesium is thermally conductive and non-magnetic, ideal for applications requiring heat dissipation and EMI/RFI shielding.

- Environmental friendliness: Thixomolding uses less energy than die-casting and produces no harmful gases. The magnesium used is recycled, contributing to sustainable production.

Thixomolding uses magnesium alloy chips heated to a thixotropic temperature (~560°C to 630°C), forming a slurry which is injected into a mold. This process produces parts with fine detail, thin walls and low porosity.

The Clayens site in Loveland has 7 magnesium Thixomolding machines, capable of producing parts of various sizes and weights, with precise dimensions and tight tolerances.

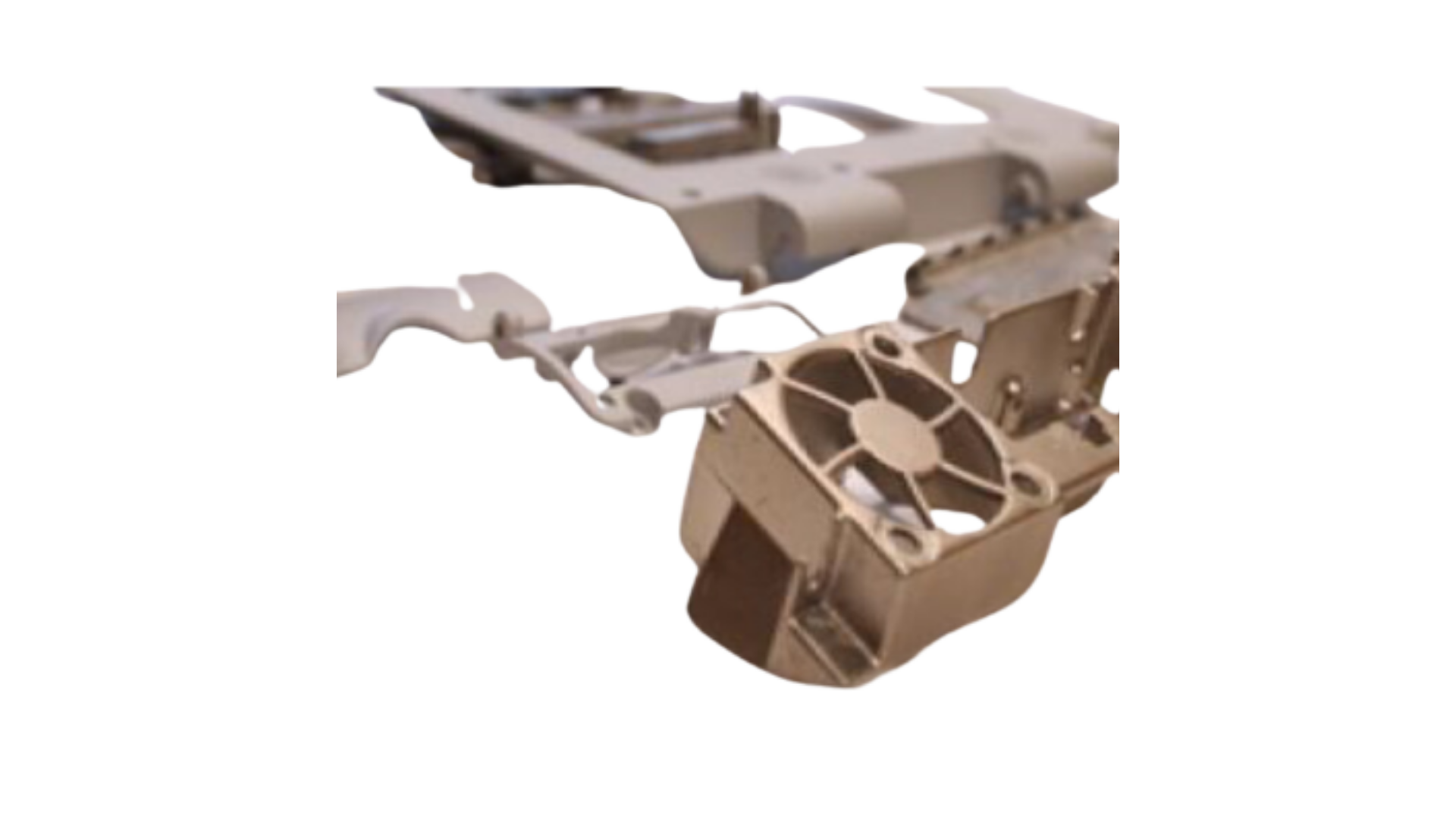

Thixomolding application cases

This versatile technology adapts to a variety of projects and needs.

Fluid manifold

The complexity of the molded details and the heat dissipation properties made Thixomolding a logical choice for this industrial hydraulic fluid manifold.

Electronic heat sink

Thixomolded magnesium was able to meet the complex design requirements, while magnesium's heat transfer properties ensured adequate functionality.

Medical device housing

Magnesium's low mass, durability and ability to mold complex patterns were key considerations in sourcing this case.

Finishes and Treatments

Conversion Coatings

Improve corrosion resistance and bonding capacity.

Electrostatic paint

Offers chemical protection and abrasion resistance.

Anodization

Electrochemical process for a durable, corrosion-resistant finish.

Nickel plating

Electroless nickel-phosphorus alloy deposition for high corrosion resistance.