Metal Engineering

As a specialist in materials processing, CLAYENS provides metal-stamping services to manufacturers.

With its high resistance to pressure and extreme temperatures, metal is a material of choice for the manufacture of springs and special parts.

Design and manufacture of metal parts / precision stamping

Metal part stamping offers a wide range of possibilities in terms of design and mechanical properties. The parts are omnipresent in vehicles and roller shutters, ensuring that the equipment functions properly. For many years, CLAYENS has been working with customers to produce:

- Stamped and assembled metal parts

- Precision stamped parts

- Stamped, bent and cambered parts

- Metal springs

Customized metal stamping

CLAYENS has in-depth knowledge of all the phases involved in the industrialization of

metal parts and offers you its expertise in the mass production of metal parts.

Manufacturing springs

Our in-house expertise covers the entire design and manufacture chain for springs of all types (compression, torsion or tension). Our teams will guide you through the long processes of specification, design, manufacture and delivery.

Stamped, folded, bent and wire parts

Metal can be freely transformed, with vast possibilities for bending and folding. We have the resources to create parts of all shapes, including cylindrical.

Design and manufacture of metalloplastic parts

Metalloplastic parts have a wide range of applications, an example of which is high-power automotive connectors. They are unique in that they combine metal and plastic to meet specific criteria, such as electrical insulation. Metal is a very rigid material that can withstand high temperatures and pressure. Plastic, on the other hand, is renowned for its insulating properties and offers greater design freedom.

At CLAYENS, we offer a comprehensive solution for your metalloplastic projects:

Strip overmoulding / Metal overmoulding / Metal-plastic assembly / Injection moulding of metal inserts

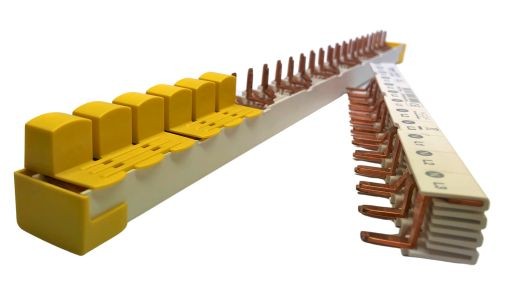

Connectors and busbars

Transporting electrical current poses major challenges in terms of safety, efficiency and strength. At CLAYENS, we can create highly complex connectors with a conductive metal part and an insulating plastic part (busbars, etc.).

Housings and casings

We can manufacture housings and other casings in their entirety or provide new solutions for your existing project. Metal provides strength and solidity, while plastic allows you to customize your casings (switches, etc.).

Stamped parts for all sectors

Proven expertise for your products

CLAYENS is committed to providing you with the right tools and advice to ensure a successful outcome to your project.

This takes the form of personalized support for mechanical designers.

Full support

We provide you with practical advice on the technical and financial feasibility of your project. We also manage the design, manufacture and delivery of your metal parts.

A comprehensive range of techniques

Our expertise, combined with a wealth of machinery (including a high-speed press), makes us the ideal partner for strip or bulk die-cutting, multi-slide cutting and heat treatment.

A wide variety of materials

To ensure that your parts achieve their precise performance, we are able to transform many different metals, including steel, stainless steel, copper, brass and bronze alloys.

Controlled quality

Our in-house processes are meticulously designed to guarantee the highest quality of parts. We are also ISO9001 / ISO14001 / IATF16949 certified.