Exploration of 3D printing technologies through an Aeronautical demonstrator

In an ever-evolving industrial context, 3D printing is emerging as an essential technology for the design and validation of complex concepts. To demonstrate the versatility and complementarity of different 3D printing technologies, we produced a demonstrator representing a scaled-down Airbus A320 engine. This project highlights the use of several 3D printing techniques and a variety of materials, illustrating their potential and specificities.

3D printing technologies used:

For this demonstrator, we used three distinct 3D printing technologies:

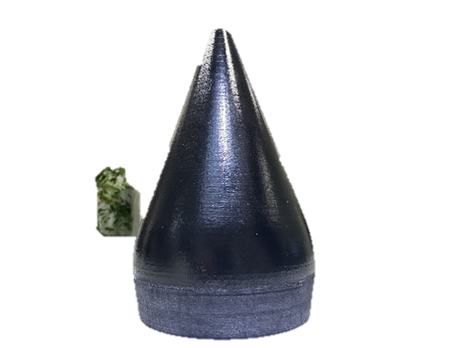

- FDM (Fused Deposition Modeling): Ideal for manufacturing functional and robust parts, this technology relies on the extrusion of melted filament. It is also distinguished by its affordable cost, making it an economical solution for prototyping and small series production. We used PLA in a variety of colors (black, gray, orange, blue, red, and white) to provide visual contrasts and differentiate the engine components.

Raise 3D E2 and BambuLab X1E

Parts made with FDM

- PolyJet: Allowing high-precision printing with fine details, PolyJet uses UV-cured photopolymers. For our demonstrator, we opted for VeroBlack material, ensuring excellent part definition and high-quality aesthetic rendering.

Polyjet Parts made with polyjet

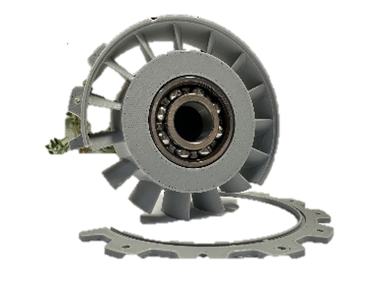

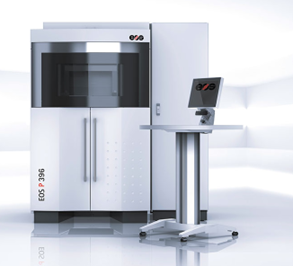

- SLS (Selective Laser Sintering): Suitable for resistant technical parts, this technology works by laser sintering of polymer powder. We used PA12 filled with glass beads (white), giving the parts good rigidity and excellent mechanical strength.

EOS P396 Part made with SLS

A demonstrator illustrating the complementarity of technologies:

This scaled-down A320 engine allows us to understand and show the advantages and limitations of each technology in a concrete situation. FDM technology was used for the manufacture of large and visible components, offering a quick and economical solution. PolyJet technology was used for parts requiring a high level of detail, while SLS technology allowed the creation of technical elements requiring increased mechanical strength.

The assembly of the different printed parts highlighted the constraints and advantages of each technology. Additionally, the integration of inserts such as bearings demonstrated the possibility of combining 3D printing with standardized mechanical components for advanced functional applications.

Conclusion

This project illustrates the richness and diversity of 3D printing technologies available within the CLAYENS group. By combining these approaches, this functional and educational demonstrator showcases the capabilities of each process and the possible synergies in an industrial context. 3D printing continues to expand the horizons of design and prototyping, paving the way for new possibilities for innovation in aeronautics and beyond.

And concretely how does this translate at CLAYENS?

The use of these different technologies is now commonplace, to improve the precision of means, remove uncertainties, accelerate deployment, and optimize our competitiveness. A recent concrete case carried out for internal needs also illustrates the positioning of each technology well (see below) and reminds us that additive manufacturing is a broad panel where each technology has its place, provided it is used wisely.

|

Technology |

Cost (€) * |

Possible Optimization |

Advantages |

Disadvantages |

|

Machining |

1660 |

N/A |

N/A |

N/A |

|

FDM |

486 |

Possible design optimization |

Rapid manufacturing, several colors and materials possible |

Surface finish to be reworked in machining |

|

SLS |

1371 |

Possible optimization by printing all parts at once (550€) |

Surface finish, strength, possible rework in machining |

High unit cost, white color, only one material possible |

|

3D Polyjet |

2182 |

N/A |

Surface finish, strength, possible rework in machining |

High unit cost, high machine cost |

*Each situation being unique, this comparison cannot be generalized.

Do not hesitate to contact us for more information!